As an air hardening grade s7 is stable for heat treatment and its combination of high machinability and dimensional stability makes it ideal for a variety of different tool and die work.

S7 tool steel machinability.

S 7 maximum working hardness is bhn 615 rc 58 s 7 incapable of meeting astm a681.

S7 tool steel is a shock resistant grade containing high impact properties.

The combination of strength and high toughness makes it a candidate for a wide variety of tooling applications.

S7 shock resisting tool steel is an air or oil hardening tool steel that is characterized by very high impact toughness.

Recommended rc 55 56 to help prevent chipping.

It has a relatively low carbon concentration compared to d2 and a2 steels 0 45 0 55 and significantly less chromium 3 00 3 50.

4110 4120 4320 8020.

Aisi s7 tool steel is a shock resistant air hardening steel.

It features excellent impact and shock resistance and decent resistance to softening at high temperatures.

S7 tool steel is a shock resisting grade with superior impact properties combined with high toughness machinability and size stability during heat treating.

S7 tool steel is a versatile formulation suitable for both cold and hot work service.

Aisi s7 steel has exceptional impact properties highest hardenability.

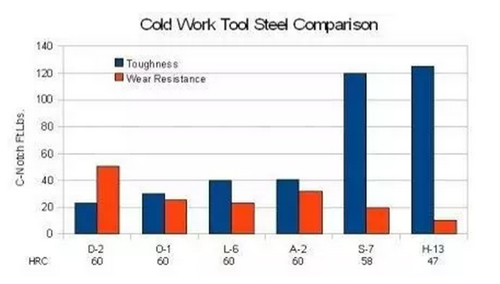

Tool steel comparison chart compare popular tool steel grades a2 m2 d2 s7 o1 using the chart below.

Its charpy a test that measures the impact strength is over 200 ft lb.

S 7 is sold in the annealed condition.

Typical annealed hardness is bhn 187 220 rc 10 18.

S 7 has a machinability rating of about 75 of a 1 carbon tool steel.

Note that a material with a machinability rating less than 100 would be more difficult to machine than b 1112 and material with a value more than 100 would be easier.

Compare grades using mechanical properties including abrasion resistance toughness size stability machinability and grindability.